Adhesive vinyl wall wraps are a popular choice for businesses and organizations in Greensboro, NC looking to update the look and feel of their interior spaces. These wraps are made from a durable adhesive vinyl material that can be printed with a wide variety of designs, patterns, and colors. They are then applied to walls using an adhesive backing, making them easy to install and remove. Adhesive vinyl wall wraps are an increasingly popular choice for corporate interior spaces, and for good reason. These wraps offer a wide range of benefits that can enhance the look and feel of a space, while also providing numerous branding functions and other purposes for customers and employees.

Here are five benefits of using adhesive vinyl wall wraps in corporate interior spaces in Greensboro, NC:

- Durability: Adhesive vinyl wall wraps are extremely durable and can withstand heavy traffic and frequent use. They are also resistant to fading, scratches, and other types of daily wear and tear, making them a great option for high-traffic areas like lobbies, conference rooms, and reception areas.

- Versatility: Adhesive vinyl wall wraps can be used in a variety of spaces, from conference rooms and reception areas to hallways, elevators, and stairwells. They are also versatile in terms of design and can be used to create a wide range of looks and feels, from modern and sleek to rustic and natural. They can be designed and printed with a wide range of colors, patterns, and images, making it easy to create a cohesive and polished look throughout a space.

- Aesthetic Appeal: Vinyl wall wraps offer a high level of aesthetic appeal for corporate interior spaces. The vinyl material itself has a smooth and glossy finish that can enhance the overall aesthetic of a space. The design options are endless, from nature landscapes, abstract patterns, to geometric designs, they can add a unique touch to any room.

- Effective for Short Term and Long Term Use: Adhesive vinyl wall wraps are an effective way to update the look and feel of a corporate interior space both in the long term and the short term. Compared to traditional wall coverings or custom-painted wall murals, wall wraps provide the same transformative effect while being easy to remove and update. Reducing the need for costly changes ensures that your new wall wraps achieve your branding goals regardless of how long your wraps need to be in use.

- Numerous Customization Options:Adhesive vinyl wall wraps can be customized to match any corporate branding or design scheme. This allows businesses to create a cohesive look throughout their space, while also making it easy to update or change the design as needed. The appeal of vinyl wall wraps is a great way to enhance the look and feel of corporate interior spaces and create a cohesive and polished look.

Applications of Adhesive Vinyl Wall Wraps

Elevator Wraps

Elevator wraps are a popular choice for businesses looking to enhance the look and feel of elevators while also providing functional benefits. They are made from a durable vinyl material that can be printed with a wide variety of designs, patterns, and colors to blend seamlessly with the surrounding wall space and create an integrated graphical experience, ensuring that branding and important imagery are maintained across multiple floors of interior spaces.

Temporary Event Graphics

Some vinyl graphics can be applied to the walls of trade show venues, convention halls, and other event spaces on a temporary basis. Event graphics can be used for trade shows, product launches, conferences, and many other types of gatherings where it’s important for branding and imagery to make a lasting impact against those of competitors.

Office Interior Graphics

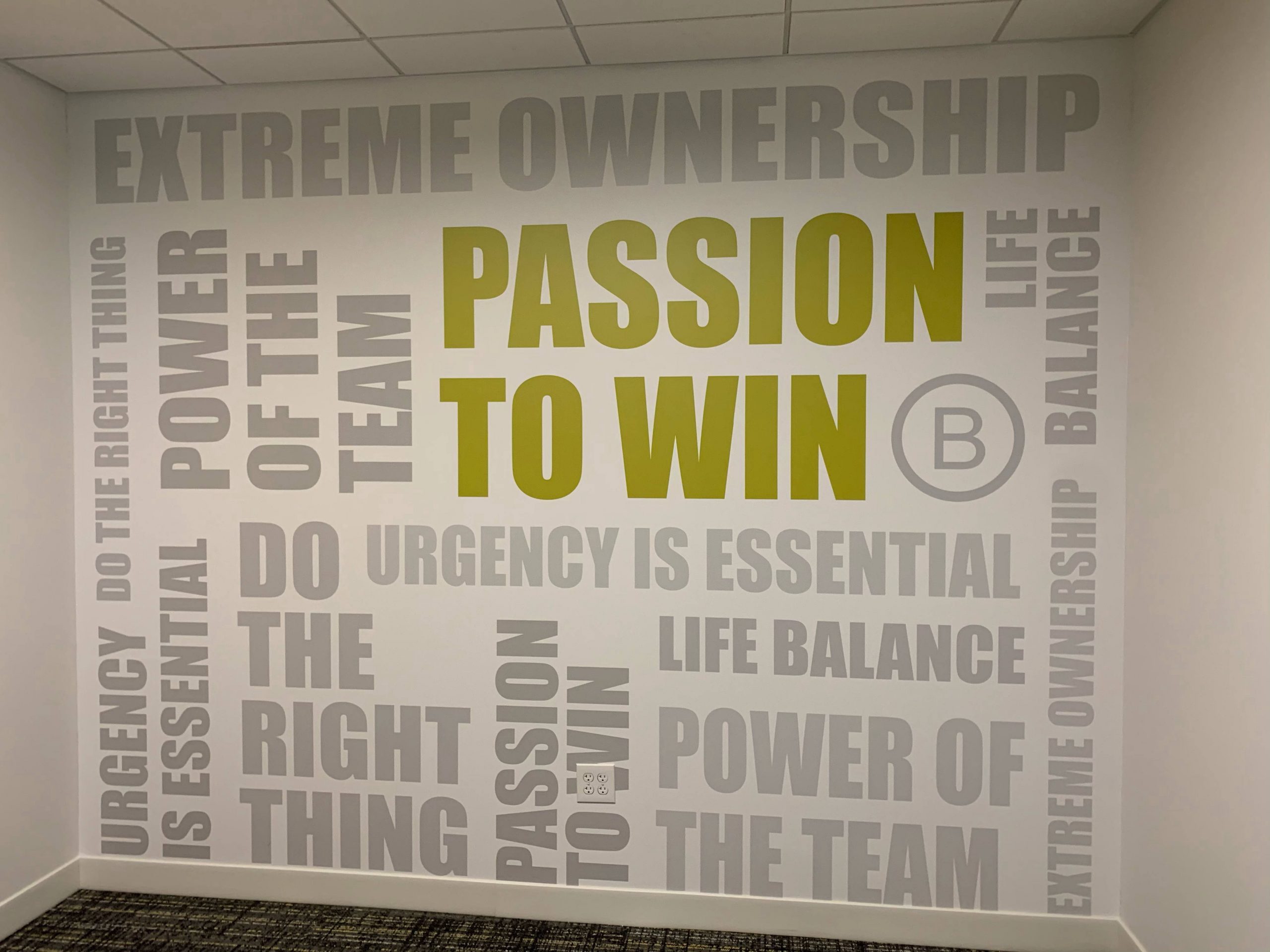

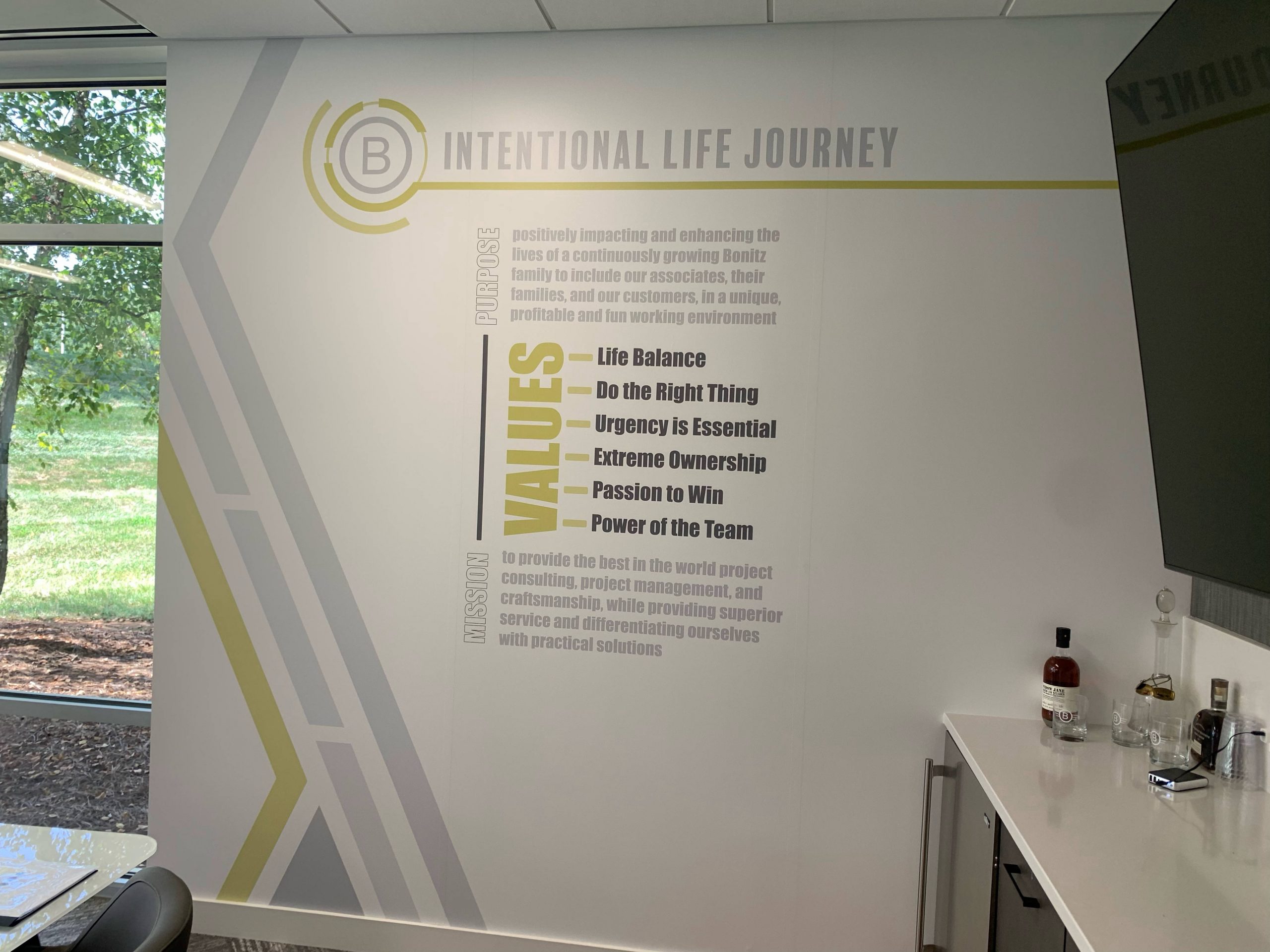

Office interiors of all sorts benefit from the enhancements provided by adhesive vinyl graphics to ensure brand consistency and maintain a vibrant corporate interior. Interior graphics can be used for a variety of purposes, such as branding, marketing, and decoration within frequently used spaces such as meeting rooms, showrooms, exhibition halls, and meeting spaces.

Interior Wallscapes

Adhesive vinyl wall wraps have other useful applications when applied in conjunction with additional signage elements such as dimensional lettering and standoff mounted signs to make interior wallscapes. Wallscapes are a popular way to enhance the look and feel of a space, using large-scale vinyl graphics and designs on the walls of large open spaces such as lobbies, hallways, and atriums to create an immersive experience.

Installing Adhesive Vinyl Wall Wraps

Adhesive vinyl wall wraps are easy to install and can be customized to match any corporate branding or design scheme, making them a popular choice for businesses of all types. Vinyl wraps can be easily removed and replaced with a new design, giving businesses the flexibility to change the look of their space as needed. Our vinyl wrap professionals adhere to the following procedures to ensure a smooth and efficient sign installation process.

Before installing adhesive vinyl wall wraps, we properly prepare the surface of the walls. This includes cleaning the walls thoroughly, removing any dust or debris, and ensuring that the surface is smooth and even. Once the walls are prepared, the installation begins. The adhesive vinyl wall wraps come with a backing that is peeled off, revealing the adhesive. The wraps can then be applied to the wall, starting at the top and working downwards. We make sure to smooth out any bubbles or wrinkles as we go and trim around edges, corners, and outlets to ensure a seamless finish.

Conclusion

Overall, installing adhesive vinyl wall wraps within corporate interior spaces is a visually immersive and captivating way to update the look and feel of an office or showroom while enhancing the experiences of both customers and employees. With proper preparation and installation, these wraps can provide a professional and polished look that can increase the overall aesthetic appeal of any corporate interior and amplify corporate branding and messaging.

Heritage Signs & Displays Installs Adhesive Vinyl Wall Wraps for Companies in Greensboro, NC, Kentucky

Heritage Signs & Displays is an award-winning commercial interior graphics and custom signage company serving clients in Greensboro, NC. We regularly serve companies, organizations, and event venues within the Kentuckiana region with impactful signs and displays that we print and install. Our talented custom sign professionals employ the latest wide format printing technology, sign fabrication techniques, and sign installation process to ensure that the displays and graphics we create are built to last. We make the process simple and collaborative for our clients, earning us numerous regional and national industry awards for our work.

To begin the process of printing your new adhesive vinyl wall wraps with us, call Heritage Signs & Displays at (502) 576-7599 or Get a Free Online Quote today!